Robotic Stacker – WSe₂ Trilayer Gated Heterostructure

Jump to navigation

Jump to search

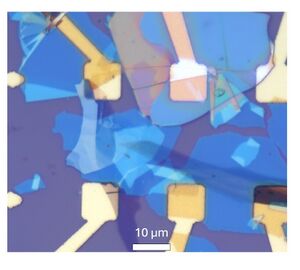

This recipe describes the MonArk NSF Quantum Foundry procedure for fabricating a WSe₂ trilayer gated heterostructure using the MonArk robotic stacking system. The process involves sequential pickup and deposition of five flakes (bold indicates gated layers)

Layers:

- Graphite (few-layer)

- hBN (15–18 nm)

- WSe₂ trilayer (contains occasional 4L, 5L+ regions)

- hBN (15–18 nm)

- Graphite (few-layer)

Stamp Preparation

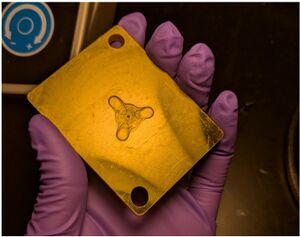

- Use a PDMS-molded stamp fabricated with PC as the polymer (see “Figure 2”).

- Brass molds are employed to shape the PDMS tip, optimized for the MonArk stacker.

MonArk Stacker Axes & Control

- A: Vertical stage of stacking finger

- B: Goniometric tilt stage

- C: Rotation stage

- X/Y: Linear translation stages

- Z: Vertical stage for focus adjustment (20× or 50× objective)

- Resolution: 0.001 mm (linear), 0.0013° (angular)

Part 1 – Pickup of Flakes

Parameters:

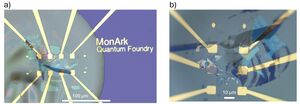

Figure 4. Stamp in contact with electrode substrate during final deposition. b) PC melting off the stamp with a circular front of PC collapsing toward center, denoted by red dotted circle. Notable feature is the finger-like channels indicated by the red arrow. Note image in b) is a different heterostructure.

- Stage temperature: 150 °C

- Contact diameter: 100–200 µm

- Wait time in contact: 1–2 min

- Pickup speed: ~0.001 mm/s

- Total time per flake: 5–10 min

Guidelines:

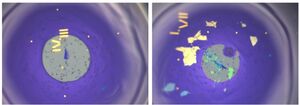

- Maximize overlap for gated flakes while ensuring electrode access.

- Rotate gated flakes to ~120° separation for three distinct electrodes.

- Position hBN layers to isolate gated flakes and avoid full coverage of subsequent layers.

Tips:

- Alternate between lowering and lifting the stacking finger to avoid sudden movements.

- Look for a grayish color change indicating successful adhesion to the stamp.

Part 2 – Deposition onto Substrate

Temperature range:

- PC flow temperature: 190 °C

- PC melt temperature: 225 °C

Procedure:

- Align stack so each graphite flake and the WSe₂ trilayer overlap independent electrodes.

- Slowly raise stacking finger in 0.001 mm steps while maintaining PC temperature between flow and melt points.

- Watch for “front” formation (PC detaching toward the stamp center) and finger-like melt channels.

- Continue until the PC fully detaches from the stamp without tearing the heterostructure.

Tips:

- Mold tips have higher curvature than double domes; avoid abrupt sliding at high temperatures.

- Adjust temperature dynamically during deposition to control PC flow rate (~2 °C/sec heating).

- When the contact front passes over the heterostructure, pause or slightly lower the stamp to prevent damage